Installation requirements

(1) After the composite rubber pad is laid on the rail joint, the track is adjusted and positioned, and the bolts, platen and other parts are placed to tighten the lower flange of the rail with the platen, then the pad and spring washers are installed, and the nut is tightened to the platen and the compression of the rubber tongue is about 2-3mm.

(2) The allowable deviation of track installation requires that the deviation of track center line position is less than 5mm of soil; Elevation difference of top surface of track ≤ 5mm soil; The distance deviation between the center lines of the two tracks was 5mm; The relative elevation difference of the top surface of the two tracks at the same position in the transverse workshop; Column < 10mm other places ≤15mm

(3) : the steel rail at the expansion joint of the plant is connected with four-hole splint. Steel trace 4kg/m, 38kg/m, 43/m, 50kg/m expansion joints can be flat joints, QU70, QU80, QU100, QU120 expansion joints are 45° inclined joints, seam width is 10mm.

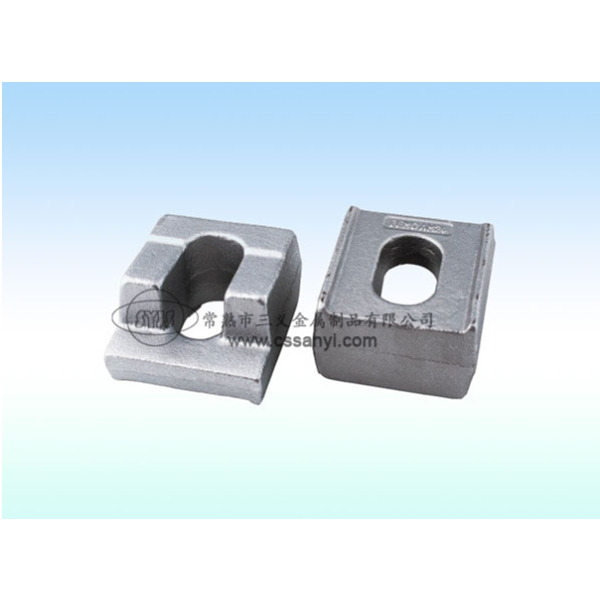

(4) : THRAIL elastic composite rubber pad is matched with track press plate. If the track press plate is QU80 type, type 7a-3 composite pad is selected.

(5) : Select bolts according to the type of pressure plate. Calculation of bolt length: I=h1+h2+h3 In the formula: h1= the maximum elevation value of concrete cushion plate after pressing plate installation (see Table I)